- Telescopes

- Overview:

Telescopes - Achromatic Refractor

- Apochromatic Refractor

- Overview:

Apochromatic Refractor - ED Refractor - less color aberration than an achromatic

- SD APO - color free 2-element APO objective

- EDT APO - 3 element ED objective

- High End APO with 3-element APO objective - no color aberation

- Flatfield APO with flat field for Astrophotography

- All Apos and EDs from all manufacturers - large overview

- TS APO and ED from Japan with high quality optics

- Overview:

- Newtonian Telescopes

- Dobsonian Telescopes

- RC Ritchey Chretien Telescopes

- Casssegrain Telescopes

- Reflektor Telescopce with Lens Correcture

- Maksutov Cassegrain Telescopes

- GoTo Telescopes

- Smart Telescopes

- Solar Telescopes H-Alpha

- Overview:

- Mounts Tripods Rings Rails Power Supply ...

- Overview:

Mounts Tripods Rings Rails Power Supply ... - Mounts Equatorial with GoTo

- Mounts Equatorial without GoTo

- Mounts Azimutal with GoTo

- Mounts Azimutal without GoTo

- Mounts GoTo - Harmonic Drive

- Travel mounts for astro imaging

- Tripods Piers Polar Wedges

- Mount Control & Electronics

- Dovetail Clamps, Plates and Mount Adapters

- Tube Rings

- Power Supply

- Counterweights Balance Weights

- Mount Accessories - Other

- Overview:

- Telescope Accessories

- Overview:

Telescope Accessories - Eyepieces

- Barlows & Reducer Lenses

- Diagonal Mirrors and Prisms

- Binocular Viewers

- Finder Scopes

- Telescope Collimation and Test

- Cleaning Tools

- Transport and Storage

- Dust protection for Telescopes & Accessories

- Stray Light Protection

- Dewcaps and Heater

- Focusers, Adapters, Motorfocus

- Telescope DIY & Improvement

- Other telescope accessories

- Replacement Parts

- Overview:

- Filters

- Overview:

Filters - Color Filters and Color Filtersets

- Nebular Filters for Visual Observing

- Neutral-Density and Polfilter

- Photo Narrowband Nebular Filters

- Photo Broadband Filters

- Photo Planetary Filters

- Photo R-G-B and IR Cut Filters

- Photo - Filtersets

- Photometric Filters

- Clip Filter for DSLR Cameras

- Filter Wheels and Filterslider

- Solar Filters for white light

- Solarfilter for H-Alpha and Calcium

- Overview:

- Adaptors

- Overview:

Adaptors - Adapter 1,25" and 24,5mm

- Adapter 2"

- Adapter T2 - M42x0.75

- Adapter M48x0,75

- Adapter M54

- Adapter SC

- Adapter M63

- Adapter M68

- Adapter to other Threads

- Adapter Extensions

- Adapter camera bayonet

- Adapter Objective Filterthread

- Adapter Quick Changing , Rotation

- Adapter Eyepiece Projection

- Adapters Tilting

- Overview:

- Astrophotography and Photography

- Overview:

Astrophotography and Photography - Cooled Cameras

- Cameras without Cooling

- Deep-Sky Cameras uncooled

- Set-Offers Camera, Filter, Wheels

- Acessories for Cameras

- Travel mounts for astro imaging

- Imaging Correctors for Telescopes

- Autoguiding Cameras & Sets

- Everything for Guiding

- Focusing aids - Bahtinov mascs

- Flat Field foils and boxes

- Lenses for Cameras

- Piggyback Camera Holder

- Camera Bags, Photocases & more

- Digital Camera and Smartphone Adapter

- Other photo accessories

- Overview:

- Binoculars, Spotting Scopes, Microscopes, Range Finders

- Overview:

Binoculars, Spotting Scopes, Microscopes, Range Finders - Spotting Scopes and Acessories

- Roof Prism Binoculars

- Binoculars with Porro prisms

- Binoculars from 100mm Aperture

- Binoculars with 1,25 inch eyepieces

- TSMX APO Binoculars

- Binoculars for Astronomy

- Binoculars Hiking Bird watching

- Monoculars - Opera Binoculars

- Accessories for Binoculars

- Range Finders

- Microscopy

- Bags for Phototripods & Binoculars

- Overview:

- Phototripods and Binomounts

- Books, Software

- Overview:

Books, Software - Books for Astronomy Beginners

- Star Charts and Planispheres

- Books about our Solar System

- Observing Tips for Amateurs

- Popular Astronomy Literature

- Teaching material

- Astrophotography books

- Telescopes, Observatories, Construction

- Calendars Yearbooks

- Software, Star Charts

- Books for Microscopers

- Books Nature and Animals

- Nature Photography TimeLapse

- Overview:

- Night Vision, Magnifiers, Weather, Domes & more

- Beginner Astronomy and Gift Ideas

- Second Hand & Special Offers

- New products

Manufacturer: Avalon Instruments

Product number: AVLINSTGOWF

EUR5906.00new

EUR 5.906,00

incl. 19 % VAT (DE)

The VAT indicated refers to that applicable in Germany. After logging in, the VAT amount is adjusted to the applicable VAT of the stored delivery country. Therefore, the final price may vary accordingly.

excl. 17.95 € shipping costs (DE)

more details to the shipping costs ...Please log in to calculate shipping costs to your country.

There are no reviews for this product

- Details..

- Technical data..

- In the box..

- Manufacturer infos..

- Safety informations..

Avalon Linear Equatorial GoTo Mount - StarGO Plus, Fast Reverse Technology

The Linear Fast Reverse is an innovative mount designed for astronomical imagingIt is manufactured in Italy by the Avalon Instruments Srl, a company with more than 30 years of experience in the field of high precision mechanics. Marketed with the Avalon Instruments trademark, this mount ranks in the medium-size mount range with a weight capacity around 20-25 kg (44 - 55 lb), imaging and observing, respectively.

The Linear Fast Reverse project rises from the passion for astronomy and mechanics taking advantage of more than 20 years of experience and testing, lots of star parties and spending countless hours under starry skies, with any types of instrumentation. Since the great majority of the problems regards the mount, both design and manufacture have been focused on realizing a mount such to overcome technical troubles.

Let´s start with the mount, which is considered the main innovation, by explaining the reasons why Avalon chose to switch from the traditional worms and gears mechanism to a new transmission system based on pulleys and tooth belts, for both right ascension and declination.

Pulleys and toothed belts, zero backlash!

This choice has allowed to obtain several advantages: a really steady motion without play (no backlash) and sudden peaks, factors of paramount relevance for long guided exposures and during high magnification visual observations. These features are of particular relevance especially for the declination axis motor that can now quickly reverse the motion without breaks to recover the plays: therefore the mount name FAST REVERSE.

The toothed belts used in the Linear have the structure made of special material with steel strands to avoid any deformation, elongation and stress, much better than those used in the automotive engine distribution system (which are generally made of rubber with nylon strands). Considering that the service time for the automotive toothed belts is around 100.000 km (60.000 miles), assuming a medium regime of 2.000 rpm and thermal stress from 0 to 90 °C (30 to 195 °F) in a few minutes, we can think that the life cycle of the Linear toothed belts will be extremely long!

It is important to underline that in the gear-worm systems the motion transmission has only one tangent point of contact, any errors on each of the two components will, sooner or later, result into a tracking error.

On the other hand, in the pulley-toothed belt system, no direct contact occurs between the pulleys, and the motion is transmitted by the belt engaging from 50% to 90% of the girth surface. Consequently any error, eventually present, is averaged among the cogs, moreover soft, greatly reducing the tracking error.

These features allow the Linear mount to perform guided exposures up to 20-30 minutes with punctiform stars even with optics of 2-3 meters of focal length.

No wear, no friction

No wearing effects since no relevant frictions occur. In fact, all the pulleys and the axes rotate on roller bearings, 13 for the RA axis and 13 for the DEC axis that allow to reduce the total friction almost to zero.

Another significant advantage of very low frictions is that the risks of motor slipping during GOTO operation is virtually null. On the contrary, it is well known the difficulty to regulate the coupling between gear and worm in the conventional mounts. If the coupling is tight the motors can stuck with consequent loss of the position, if the coupling is too loose the play increases.

On the other hand, the absence of significant play in the Linear makes the initial calibration of guiding CCD quick and easy.

No lubrication, no maintenance

Since there are no gears, there is no need of periodical lubrication of the internal components and therefore the maintenance is extremely reduced and limited to the external cleaning.

Concluding remarks

The Linear mount is specifically designed for mobile astroimagers, with some peculiar features:

In short, the Linear Fast Reverse mount mount is ideal for those travelling astroimagers seeking for long deep-sky exposures, even with long focal lengths, by means of an high quality, light, reliable, accurate and easy-use setup, with an excellent quality/performance-to-cost ratio.

StarGo Plus controller

The Linear mount with the StarGo Plus controller improves its max slew speed up to 6° / sec and the microstepping up to 128 adjustable.

| Type: | German equatorial mount |

| Weight: | 12 kg (26.4 lb), without counterweight and bar |

| Capacity: | 20 kg (44 lb) in imaging, 25 kg (55 lb) in observing |

| Construction material: | Anodized aluminium, worked out from single blocks with high precision 5 axis CNC machines |

| Transmission system: | All belts drive system based on four stages reducer. Pulleys made with special glass fiber polymer and high precision tooth belts. All the movements are on ball bearings. No maintenance and no backlash system. |

| RA Axis: | Heavy duty steel, diam. 35 mm; 1x dual ball bearing diam. 62 mm + 1 roller bearing diam. 72 mm + 2 roller bearings diam. 45 mm - on bearings clutch system |

| Dec Axis: | Heavy duty steel, diam. 35 mm; 1x dual ball bearing diam. 62 mm + 1 roller bearing diam. 72 mm + 1 roller bearing diam. 45 mm - on bearings clutch system |

| Tripod connection: | Pre-bored holes in different circle diametres (e.g. for Baader tripod etc.) |

| Scope plate: | Losmandy, 3" (75 mm), dovetail, single knob with 2 tightening points |

| GoTo system: | StarGO Plus GoTo control system WIFI version |

| Polar finder: | Skywatcher model (optionally Losmandy model) |

| Counterweight bar: | Quick release, 30 mm diam. (1.181"), stainless steel bar |

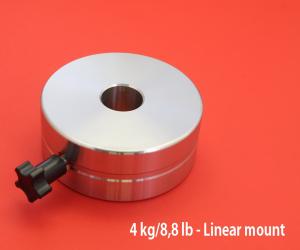

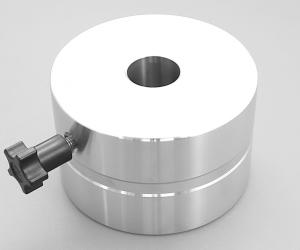

| Counterweight: | Stainless steel 6 kg (13.2 lb) |

| Manufacturer / Importeur: | Avalom Instruments |

| Street: | Via Pontina Vecchia KM35 |

| ZIP / City: | 04011 Aprilia (LT) |

| Country: | Italy |

| Telefon number: | +39 06 87153197 |

| Email: | info@avalon.instruments.com |

| Website: | www.avalon-instruments.com |

Safety informations: PDF Download

Recommended accessories

Accessories for mounts

Adaptors

Customers who bought this product also bought...

General Accessories

Photo Acessories

Power Supply

Similar Products

Avalon AV-1LNR002 Linear StarGo GoTo Mount - Bluetooth

EUR 5.070,00RRP EUR 5.415,00you save 6.4% (EUR 345,00)

Reviews